A relatively inexpensive 3D-printed model of a patient’s blood vessels is as effective as current commercially available models for training medical students in interventional radiology vascular access, according to a study presented at the Society of Interventional Radiology’s 2018 Annual Scientific Meeting.

“We have come up with a viable method for creating something that is inexpensive and also customisable to individual patients,” said Alexander Sheu, an interventional and diagnostic radiology resident at Stanford University School of Medicine, and lead author of the study. “The current model used to train medical students lacks the ability to replicate a patient’s anatomy. Our 3D-printed model will provide students a more realistic experience, allowing for better preparation before they perform procedures on real patients.”

The researchers tested medical students’ comfort in using a 3D-printed model, compared to commercially available models, to simulate ultrasound-guided access through the femoral artery in the groin.

Thirty-two students were randomised to practice with the 3D-printed model or the commercial model in a simulation experience developed by the authors of the study. Prior to the simulation exercise, 73% of the 3D group and 76% of the commercial-model group indicated that they did not feel confident in performing the procedure. After the training, most of the 3D model and commercial model trainees agreed that their respective models were easy to use (93.3% and 94.1%) and helpful for practice (93.3% and 94.1%). Additionally, confidence in performing the procedure, known as femoral artery access, increased a similar amount in both groups.

“Now that we know that a 3D-printed model is just as effective at training medical students in this type of procedure, this simulation experience can be made available to even more trainees and potentially improve procedural skills for residents, fellows, and attendees,” said Sheu. “We foresee this really making an impact in the world of interventional radiology training.”

“Now that we know that a 3D-printed model is just as effective at training medical students in this type of procedure, this simulation experience can be made available to even more trainees and potentially improve procedural skills for residents, fellows, and attendees,” said Sheu. “We foresee this really making an impact in the world of interventional radiology training.”

Medical simulation exercises are playing an increasingly larger role in medical training; especially in the field of interventional radiology. Many commercially available devices cost between US$2,000 and US$3,000 each, while 3D printing has the ability to produce practice models inexpensively and more realistically, the authors said.

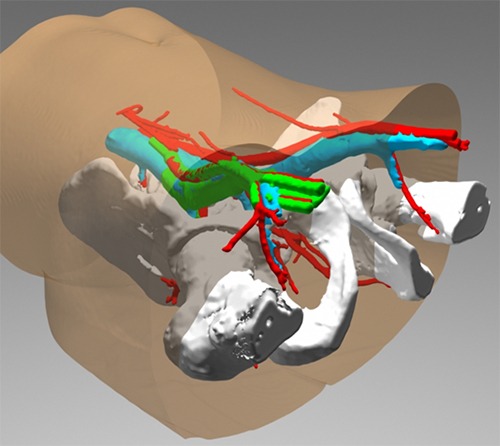

The 3D-printing technology can reproduce a patient’s exact vessels based on a CT scan and produce an ultrasound-compatible vascular access model that is unique to that patient’s anatomy. To adapt the 3D printing technology to their needs, the researchers used a tissue-mimicking material that was durable to withstand punctures, but still felt realistic. This tailoring allows trainees to practice with variations in anatomy before they encounter them during a procedure, which may help to lower complication rates, researchers said.